Ericsson’s Connected Logistics Chain — a New Vision for the Modern Supply Chain

Get the latest in your inbox

Get the latest in your inbox

Ericsson combines their expertise in communications technology and network design with a Stardog knowledge graph to create the Connected Logistics Chain, a new global shipping platform.

Ericsson has been making telephones for almost 150 years; but today, they produce and ship the hardware that make 5G networks a reality. While growing their global telecom business, Ericsson was struck by the inefficiencies in a slightly different network:

When we looked within our own logistics, we found that to facilitate a single shipment by air, 21 documents must be sent 40 times in 20 different steps. The volume of paper-based shipping documents created each year alone could fill an entire Boeing 747 freighter.

- via Digital supply chain transformation – sharing data to unlock the potential in logistics

This reliance on paper is a byproduct of the complex, fragmented, and distributed nature of the supply chain. Each time a shipment changes hands — from ocean to rail, air, and road and between importers, exporters, customs agents, and freighters — the shipment is assigned a new unique identifier. Paper documents are the primary means to track these shipments during handoffs, slowing airfreight to the speed of a bicycle. The digital systems that do exist are primarily peer-to-peer connections or only focus on one part of the supply chain, leaving little to no flexibility to share data between multiple parties.

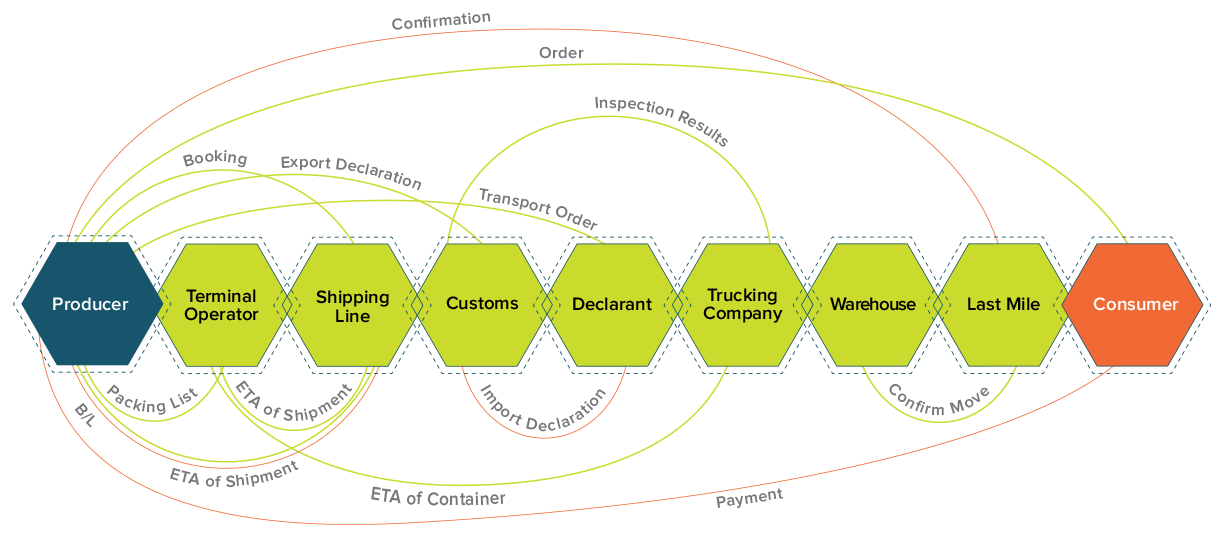

The actors in a typical supply chain suffer from siloed, peer-to-peer links between systems. Image adapted from slides presented at Internet of Supply Chain Conference 2019.

So what led Ericsson, nominally a telecom company, to solve the global logistics problem? It was the realization that the supply chain is fraught with the same issues Ericsson had faced while developing telephone networks — technology silos in a horizontal industry.

When the original telecom systems were installed, they required peer-to-peer connections. Each individual telephone had to be manually connected to every other telephone. These created silos between operators, which only proliferated as mobile network technologies developed independently and divergently. With no global standard in place, you needed a different phone number to call into different networks in different parts of the world. Eventually, competing companies collaborated on a global standard for phone numbers so their customers could place a call to any country, from anywhere, on any network.

Similarly, without a global logistics standards, supply chain information stays trapped in those paper documents — creating a black box around shipment status and resulting in slow, costly, and unpredictable operations. So Ericsson devised a way to break down the supply chain silos, creating a new global standard that provides the visibility required to reduce these inefficiencies.

At the Internet of Supply Chain conference last month, Ericsson Intrapreneur Thomas van Bunningen presented Ericsson’s vision for the Connected Logistics Chain: a scalable, digital, and transparent logistics platform.

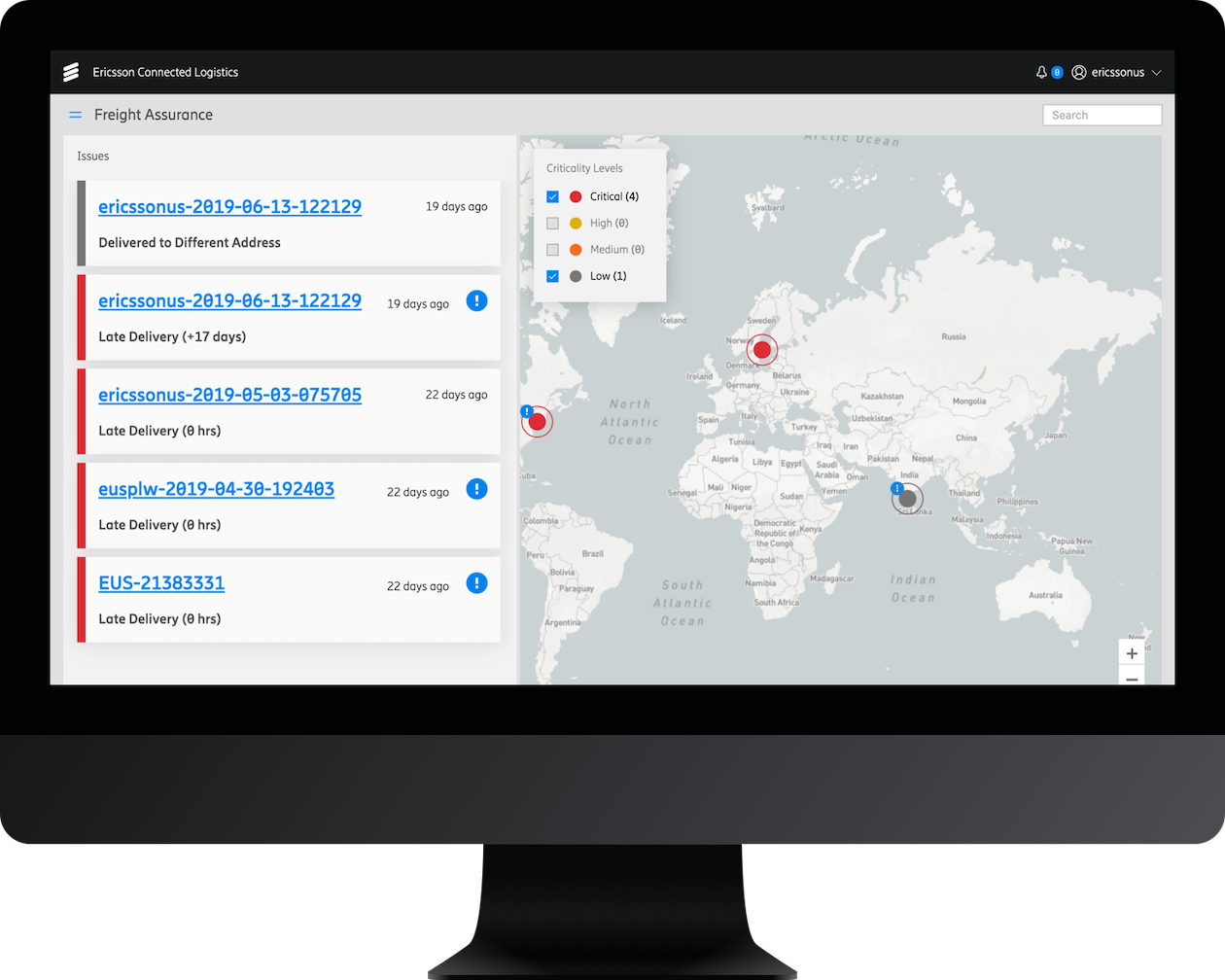

The Connected Logistics Chain allows all actors in the supply chain to securely share information via API in order to trace shipments. Image via Ericsson.

The Connected Logistics Chain brings together all the actors in the supply chain, offering full visibility on shipments during their journey from producer to consumer. The CLC promises to solve some of the major issues affecting manufacturing:

To crack open the black box of logistics, Ericsson needed to solve a data problem — figuring out where any given object is at any given moment — and a communication problem, eliminating the peer-to-peer silos across the supply chain. Ericsson turned to the Internet of Things (IoT) to address the first data issue. Attaching sensors, scanners, RFID readers, and QR codes to each object in the supply chain and ingesting the streams of data into the cloud meant that, theoretically, someone could know where every shipment was, no matter where it was along its journey.

However, generating more data wasn’t enough to fix these siloed peer-to-peer networks. To make that data accessible and actionable for all parties, Ericsson sought a technology that was based on open standards, allowed participating companies to maintain their existing tracking systems, created an open ecosystem, with the attendant network effects, and offered robust security controls for data owners to maintain complete control of the data they share. Only Stardog checks all of these boxes.

Stardog’s data unification platform is based on a family of standards including RDF, which is designed to represent information — and all its complexities — in a machine-understandable way. Ericsson leveraged this technology to build a fully interoperable platform offering secure data-sharing that doesn’t disrupt the existing technology investments of its participants.

Ericsson’s CLC accomplished this by translating the different data dialects embedded in legacy systems into the standard language of RDF. Subscribing companies can leave their data in place and push the relevant information into CLC. Because this transformation occurs within an overarching data layer, legacy systems are left intact. Each company controls their own data and systems, only publishing the data relevant to the rest of the supply chain. Further, the data model can scale organically. The CLC incorporates new and different types of data with simple changes to the data model, leaving the fundamental architecture intact.

With so many data collaborators, security is critical. CLC uses Stardog’s flexible data modeling capability to dynamically set and manage access controls. Each data owner publishes and controls who has access to the data; this access can be cascaded to reflect real-life business processes. Additionally, the CLC uses blockchain to create a publicly verifiable ledger of the shared data, reducing the risk of tampering and errors.

Ultimately, the key for Ericsson was RDF’s ability to represent a unique ID for every logistics object and associate related items to their correct ID. Products, boxes, pallets, trailers, containers and freighters have their own unique ID, all of which are linked together in the CLC. Now it doesn’t matter at what level you’re monitoring the supply chain, you can see when your plane landed and exactly which parcels are onboard. With a unique ID there is no need to re-label objects with a different ID as they pass through the chain of custody, simplifying the supply chain and providing visibility across the board. The shared unique ID reduces the need for paper tracking, cutting down on potential for human error as well as greatly benefitting the environment.

The unique ID part of the RDF standard, each object is assigned a Universal Resource Indicator (URI) to which all related documents and records are linked. Image via Ericsson.

The unique ID also serves as the basis for a digital twin by providing near real-time monitoring of shipments throughout the supply chain. (A digital twin is the online counterpart of a physical object, and through sensors it keeps in sync with the physical state — location, atmosphere, damage — of its twin.) For the first time, all participants in the supply chain have unparalleled visibility into the black box of logistics. Information on location, packaging, delivery, and carrier are at the fingertips of every interested participant.

Operating on a global standard offers companies the visibility they require to reduce operational inefficiencies and better serve their customers. With the Connected Logistics Chain, Ericsson is advancing from their telecom roots of connecting everyone to truly connecting everything.

How to Overcome a Major Enterprise Liability and Unleash Massive Potential

Download for free